9:00am - 5:00pm CST

|

Customer Service, M - F : (630)739-5200 9:00am - 5:00pm CST |

|

||

|

|

|||

|

|

Copyright 1999 - 2020 Chef Depot Inc.

All Rights Reserved.

Legal Notice and Copyright

Customer

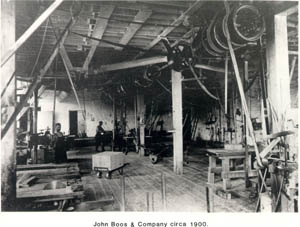

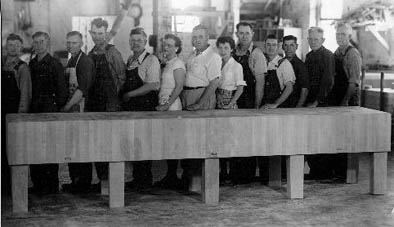

Service - E-mail us " John Boos " or phone:(630) 739-5200

![]()

Customer Feedback